Field hockey is more popular than ever. The team sport is proving particularly popular with young people. Hockey has been played on synthetic turf since the 1970s. Not least because the even carpet of turf with short blades delivers optimal conditions for a fast and precise game. With the latest generation of synthetic turf – the Poligras Tokyo GT – Polytan has succeeded in upgrading the young and modern sport with the sustainability component. The turf blades consist of up to 60% bio-based plastic from sugarcane. This was made possible through the Green Technology programme, with which, Polytan aims to advance sustainability in sport as an innovative company.

Sustainable products for sustainable consumption

The aim of the Green Technology innovation programme is to bring environmentally friendly products with an improved life cycle assessment to the market and contribute to more sustainable consumption. For a plastics processing company, this is not an easy task – other industries have a much easier job here. Bio-based plastics and a CO2-reducing production process have proved to be an ideal solution for Polytan. These will gradually replace the conventional raw materials and production processes at Polytan.

Green technology starts with three environmentally friendly products

By the summer of 2019, the Green Technology programme, which was launched in 2017, already included three product innovations: the Fusion Infill GT infill granules, the PolyBase GT elastic layer and the Poligras Tokyo GT hockey turf. These environmentally friendly products were developed in close collaboration with the world’s leading (bio)chemicals companies Braskem and Covestro. The infill specialist Melos, part of Sportsgroup Holding, also contributed its expertise. The letters ‘G’ and ‘T’ in the product names stand for green technology. And the “Tokyo” in the name Poligras Tokyo GT was also chosen for a very specific reason – the hockey turf was developed with the 2020 Summer Olympic Games in Tokyo and the 2022 Hockey World Cup in mind. Polytan was awarded the contract in 2016 as a “Global Partner” of the International Hockey Federation (FIH).

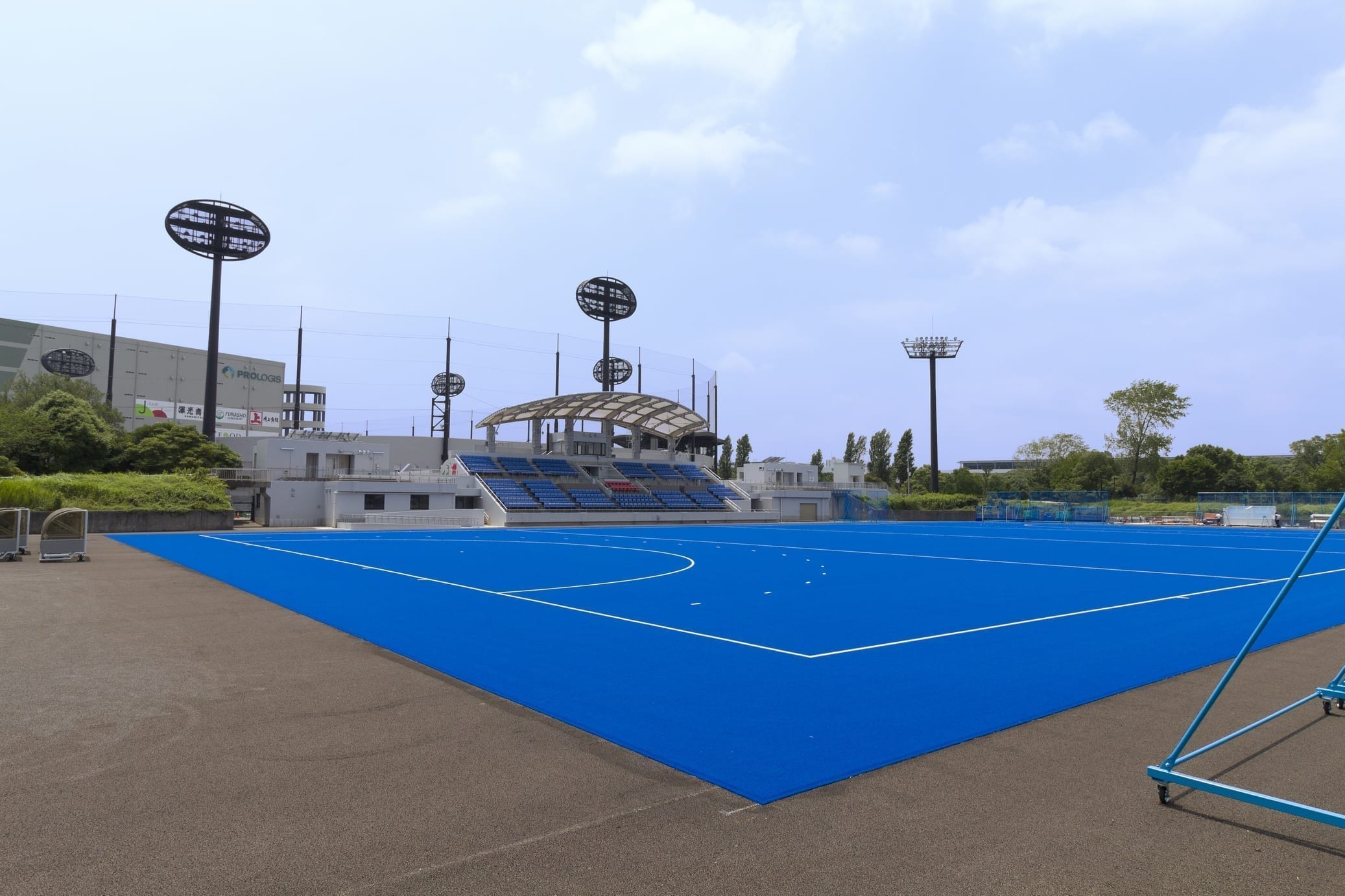

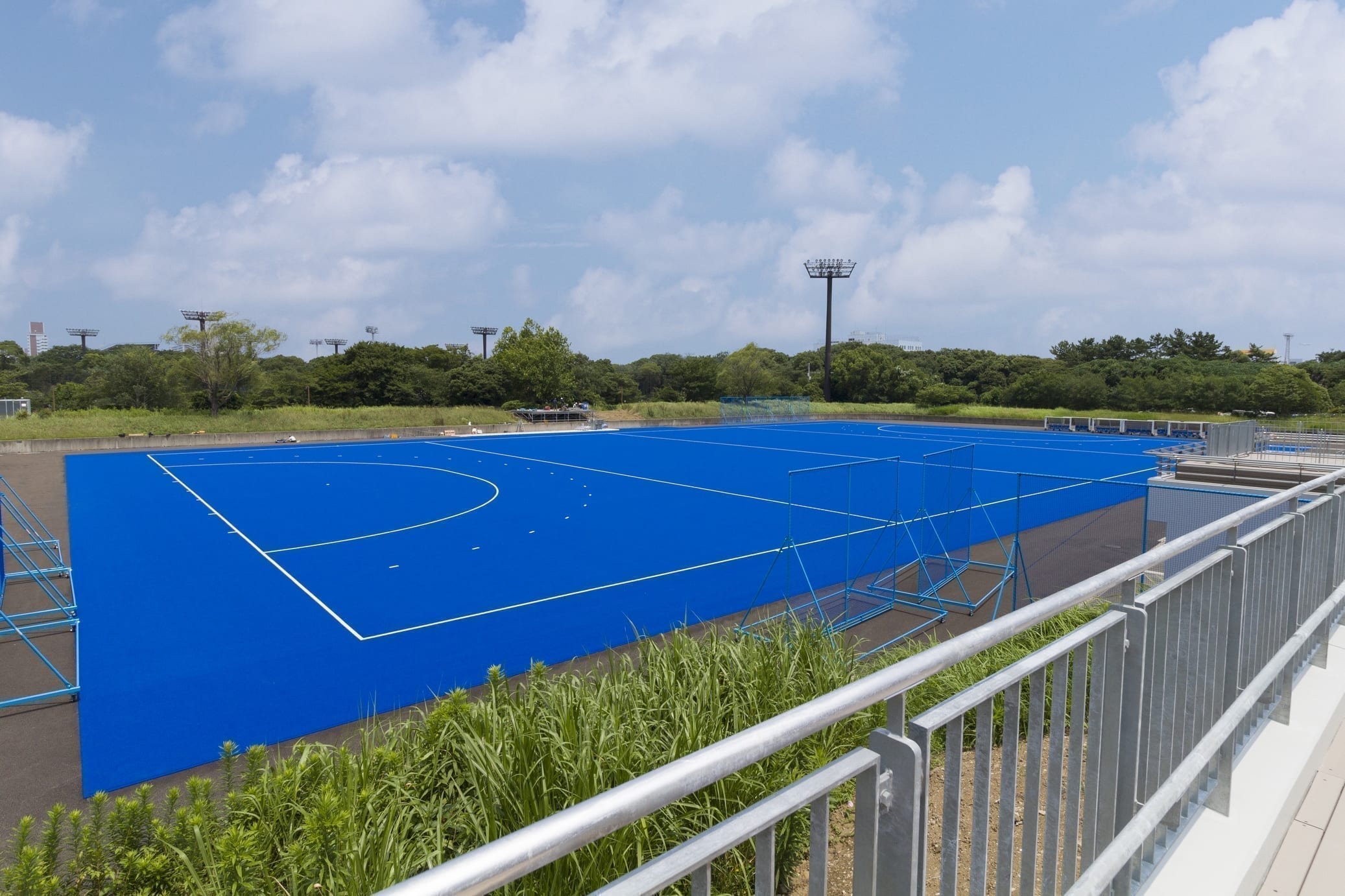

Poligras Tokyo GT for the 2020 Olympics

In summer 2020, the first carbon-neutral Olympic Games will take place – this is the aim of the organisers. An aspiration to which Polytan, as an innovative company in the field of environmentally friendly sports surfaces, can contribute. The Poligras Tokyo GT synthetic turf system, which was specifically developed for the competitions, has a significantly better environmental footprint than any previous synthetic turf system. A further advantage is the optimised turf quality: Never before has a hockey turf had a longer ball roll distance – it has been improved by about 15 percent. This means that fast and exciting hockey games are essentially guaranteed, increasing the attractiveness of the competitions.

FIH Pro League games are already being played on Poligras Tokyo GT

The FIH Pro League 2019 gave a preview of what’s to come: As part of this top-class international hockey tournament, competitions have already been held on the new synthetic turf: both in the Mönchengladbach Hockeypark, and at the Crefelder HTC in Krefeld. In the case of the Crefelder HTC, this was the world’s first installation of the environmentally friendly Poligras Tokyo GT product. But what is it that actually makes the synthetic turf so sustainable? The I´m greenTM polyethylene from the Brazilian global market leader Braskem is primarily responsible for the positive life cycle assessment.

Renewable resources instead of consumption of fossil resources

Until now, Polytan had been producing all the turf fibres of its synthetic turf systems exclusively using high-quality polyethylene – a non-toxic, petroleum-based plastic that is extremely easy to recycle. In the case of the Poligras Tokyo GT, 60 percent of this material is now replaced with the bio-based I´m greenTM polyethylene. This is made from the renewable resource of sugarcane.

Bio-plastic from sustainable sugarcane cultivation

Bio-based plastic made from sustainable sugar cane is only a real alternative for Polytan for conventional raw materials production, if plant cultivation which is compatible with humans and the environment is guaranteed.

With this in mind, the Brazilian sugarcane plantations are primarily used for the production of table sugar and for the production of bioethanol (fuel). The fields are far from the Amazon and do not require artificial irrigation. Only the third sugarcane pressing – which is not high enough in quality for sugar production – as well as the molasses serve as the basis for bio-polyethylene production. Another by-product of sugarcane pressing is the bagasse: this is used to generate CO2-neutral energy, which is used for the production of sugar and ethanol. This has a direct positive effect on the CO2 footprint of the I´m greenTM bio-based plastic from Braskem. Finally, the bagasse is burned and the ashes return to the sugarcane fields as organic fertiliser. A closed, almost ideal economic cycle has emerged.

This provides a 2.62 tonne CO2 relief for the environment

When it comes to quality, the bio-polyethylene produced is in no way inferior to conventional, petroleum-based polyethylene. And yet, the carbon footprint of the sugarcane plastic from Braskem is extremely positive: No climate-damaging CO2 is released during production, in fact some is even absorbed from the atmosphere.

For one tonne of bio-polyethylene, the environment is relieved of 2.77 tonnes of CO2 – compared with the production of one tonne of conventional polyethylene, where around 1.9 tonnes of climate-damaging CO2 are released. This excellent environmental balance, even after being transported from Brazil to Europe to Polytan’s synthetic turf production facilities, remains almost intact – slightly decreasing to 2.62 tonnes of CO2 relief for the environment.

Poligras Tokyo GT synthetic turf made from 60 percent bio-polyethylene

The turf blades for the 2020 Olympic Games and the 2022 Hockey World Cup consist of 60 percent bio-polyethylene and 40 percent petroleum-based polyethylene. The use of 100 percent bioplastics would be technically possible and desirable for sustainable consumption, but is currently not feasible due to the higher costs. Nevertheless, the environmental balance can be seen with a mixture ratio of 60:40: With a proportion of bio-based materials of 60%, almost 2 tonnes of CO2 are saved per tonne of used materials for the turf filaments. In the case of an entire synthetic turf hockey pitch, the total comes to approx. 28 tonnes of CO2. In fact, 28 tonnes corresponds roughly to the amount of CO2 stored in three hectares of German forest.

Green Technology from Polytan for more sustainable products in sport

The transition to becoming a sustainable company poses major challenges for plastic processing manufacturers in particular. With three environmentally friendly products (as of July 2019), Polytan has already launched successful examples that prove that this is possible. The decisive factor here is the choice of partners and raw materials. For the new synthetic turf system for hockey, the Poligras Tokyo GT, the renewable I´m greenTM polyethylene is used, which is produced CO2-neutral and under fair working conditions by Brazilian global market leader Braskem. Without rainforest deforestation, without dedicated cultivation areas. In this way, the product contributes to the desired goal of CO2-neutral Olympic Games at the Olympic hockey facilities for Tokyo 2020. Not only does the hockey turf display outstanding performance in terms of its environmental impact, but the playing characteristics have also been significantly improved – as the environmentally friendly product was able to prove as part of the FIH Pro League in the Mönchengladbach Hockeypark and the Crefelder HTC.