After looking at bio-based raw materials as the basis for Green Technology in the first part of our blog series on sustainability and environmental awareness at Polytan, we are now turning our attention to recycled plastics. We return these materials to the plastic cycle and incorporate them into selected synthetic turf systems in the form of recyclate.

(2) Incorporating recycled plastics

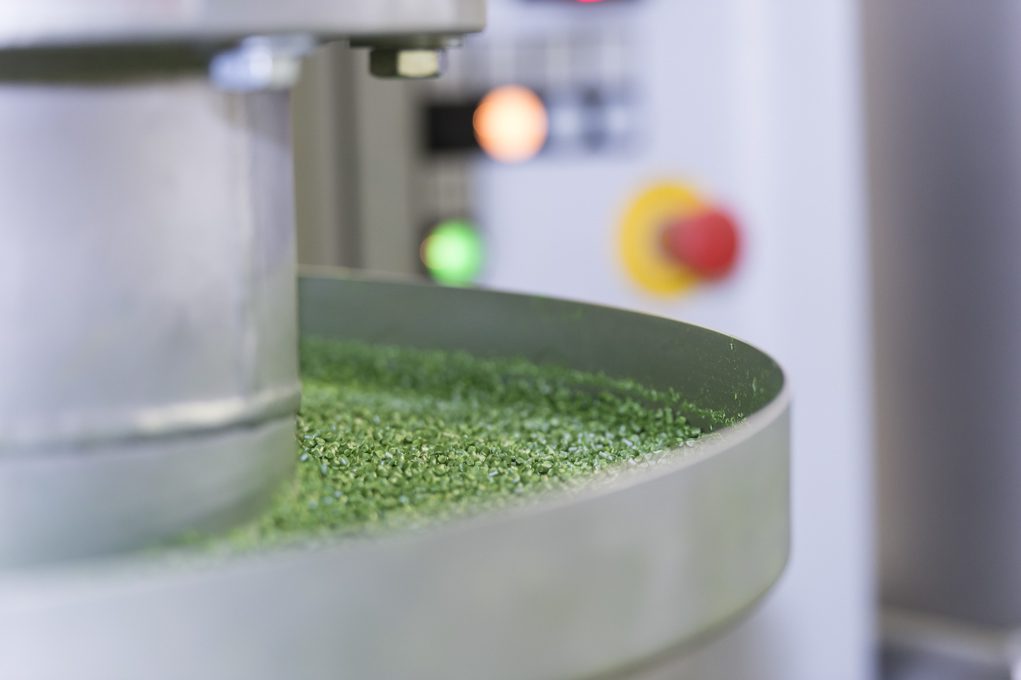

Apart from bio-based I’m green products, Polytan has been following two other paths to increase sustainability and lower its environmental impact since 2021. One such path is PCR (post-consumer recycling) – recycling plastics that have been used previously. We return these materials to the plastic cycle and incorporate them into some of our synthetic turf systems in the form of recycled granules.

To do so, PCR materials are mechanically processed and then returned to the plastics cycle; a distinction is drawn here between mechanical recycling and feedstock recycling. While the high degree of purity of the recycled PCR materials is demanding, it is ultimately crucial. This is why Polytan only uses mechanically recycled plastic granules for our LigaTurf Cross GTR, for example.

LigaTurf Cross GTR

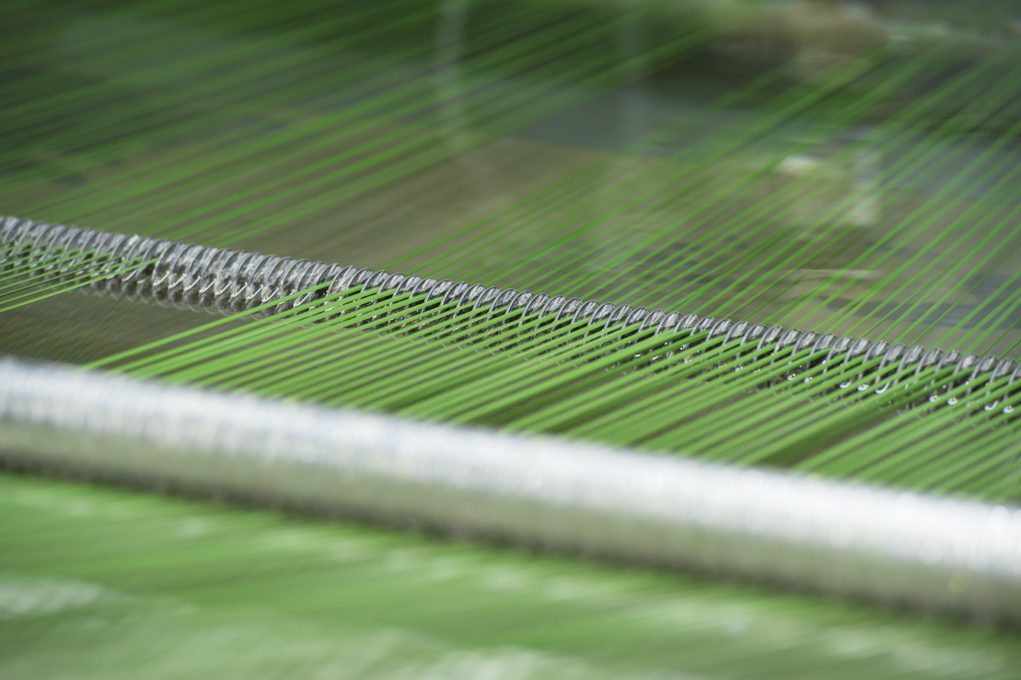

As with the tried-and-tested LigaTurf Cross system, LigaTurf Cross GTR uses straight and textured filaments, i.e. two different fibre types that give the surface an inimitable football turf feel and impressive volume. Both filaments now also use PCR materials recovered as part of the recycling process. The straight filaments contain at least 20% recycled plastics.

Since the textured LigaTurf Cross GTR fibres are also made of up to 80% organically based plastic (I’m Green™ polyethylene), this is the first football turf to combine bio-based and recycled materials. Moreover, the surface’s environmental footprint benefits from our “green” production: we use up to 100% green electricity in the production of LigaTurf Cross GTR. The 100% PolyCoat PU wear coat also reduces material and energy consumption during production. The resulting LigaTurf Cross GTR is a low-maintenance, durable synthetic turf for training and sports facilities that not only fulfils the requirements of professional athletes, but elevates climate protection and sustainability to a new level in the world of synthetic turf systems – and for this reason alone offers investors and operators an interesting and particularly sustainable perspective.

Conclusion and outlook:

Recycling is playing an increasingly important role in terms of sustainability and lowering our environmental footprint – for us too. Thanks to our LigaTurf Cross GTR, we are already able to offer a surface that integrates recycled plastic and thus returns it to the plastic cycle. Furthermore, we would like to gradually change our existing product portfolio and also incorporate recycled materials in our production in the future. To improve the quality of PCR materials and mechanical recycling separation technology, Polytan is currently seeking to establish a close cooperation with major recycling and re-granulation companies, as well as with certification companies to determine and use carbon footprints. The ISCC Plus certification provides proof that PCR materials are being used.

In our third and final instalment in this blog series, we will be exploring a new chapter and will present a general overview of how our recently founded sister company FormaTurf comprehensively recycles old synthetic turf surfaces.