In our third and final instalment of this blog series, we walk you through how our recently founded sister company FormaTurf GmbH is about to help Polytan set new industry standards in sustainability thanks to the comprehensive recycling of old synthetic turf surfaces.

(3) Recycling synthetic turf systems

As the German market leader in synthetic turf systems, Polytan and its parent company Sport Group is also committed to being a trailblazer in terms of the environment. Our sister company FormaTurf, for example, was recently established to allow us to markedly enhance our sustainability strategy.

Thanks to a state-of-the-art recycling facility currently being built on an area covering around 20,000 square metres in the German city of Essen, the new company will soon enable us to fully recycle old synthetic turf systems, thereby closing the value creation chain – from research and development, production, installation and maintenance to sustainable recycling.

Production at the recycling plant is expected to begin in the second half of 2022.

The disposal dilemma

Synthetic surfaces need to be replaced after 12-15 years of use, depending on the quality of the original materials used, maintenance and usage.

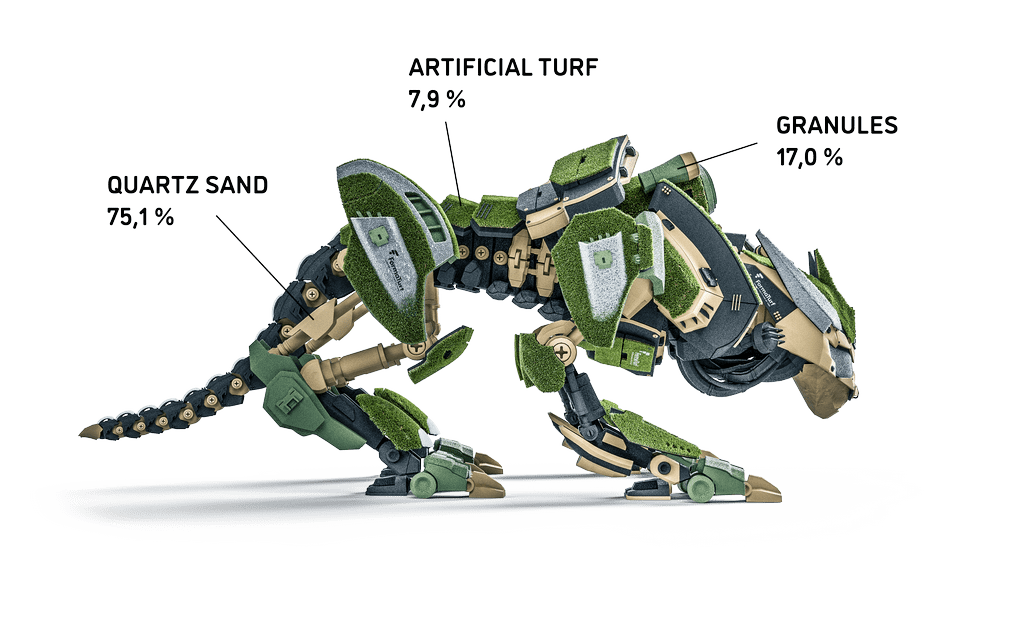

Until recently, the sheer quantity of material that needed to be disposed of at the end of a lifecycle was problematic. Removing a large synthetic turf pitch of approximately 7,000 square metres, for example, generates around 200 tonnes of waste.

And the wastes “quality” was also lacking: a wide variety of materials, some of which have been exhausted and worn out by playing, but also by UV exposure.

Compounding the issue, there are about 6,000 synthetic turf pitches in Germany, many of which are approaching the end of their lifecycles. The need for replacement surfaces is likely to continue to grow in the future simply because more and more synthetic turf pitches are being installed around the country.

Rising to the challenge

Up to now, some discarded synthetic surfaces were thermally recycled or pressed and then exported – solutions that fell short of sustainability standards.

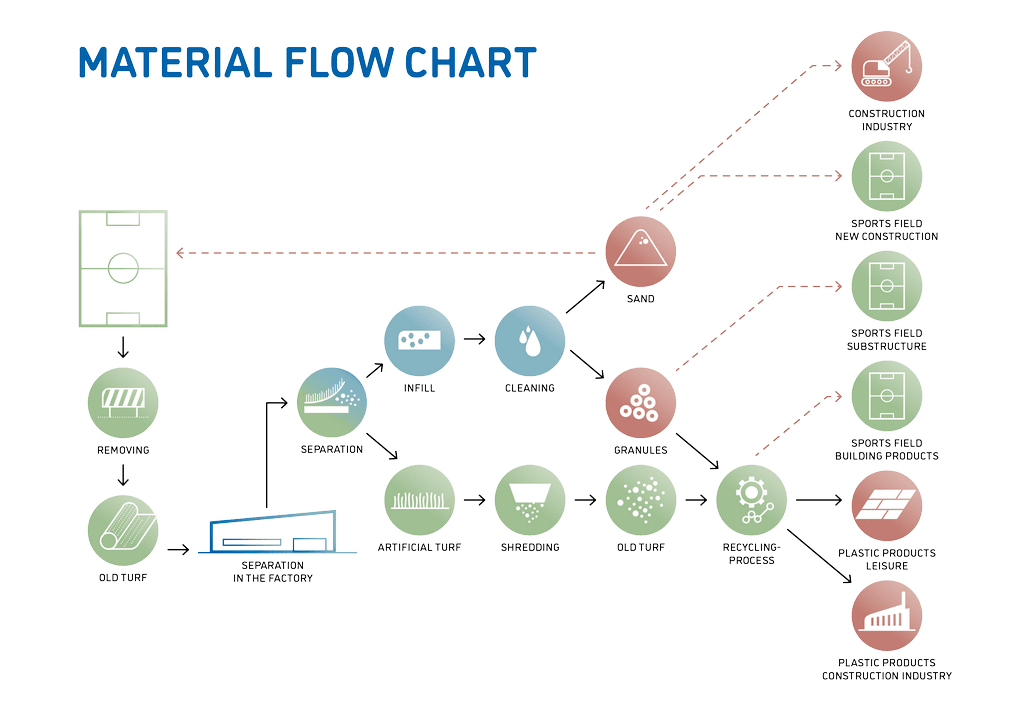

It is for these reasons that Polytan decided to tackle the challenge head on with FormaTurf, a subsidiary of Sport Group Holding GmbH that was founded in November 2021. Through the new company, discarded synthetic turf systems will now be recycled in a sustainable, holistic and transparent manner, with 100 percent of the old artificial surfaces being put through the recycling process. This means that for the first time, turf backing, filaments and infill will all be included in the recycling loop.

The recycling process: Beating out

The first step in the recycling process after the synthetic turf is removed is known as ‘beating out.’

Sand accounts for around 70% of the weight of an artificial surface, so as much sand and infill as possible needs to be separated from the turf backing and filaments during this initial stage. The sand/infill mixture is then separated and cleaned, with purity levels of 99% possible. The sand is then dried and can be used again as infill on new or existing synthetic turf pitches.

Shredding, heating and fusing

Some grains of sand will have partly bonded with other substances during the service life of the synthetic turf surface and therefore remain even after the beating out stage.

To allow for further recycling, the turf backing (including filaments) is shredded into millimetre-sized pieces and mixed with the separated infill material, a process called ‘aptrusion‘.

Aptrusion, for which FormaTurf has applied for a patent, allows for a sand content of up to 75%.

New products

The turf carpet and rubber granules are then processed into new plastic products, including edging stones, lawn grids and modular flex bricks, and can be used in the construction of new sports fields. Other applications include compost systems, raised beds, panels for carports, partitions for sports fields and plastic paving stones. Some of the new products, for example nailer boards, can even be used again for the installation of synthetic turf systems.

Maximum transparency

Throughout the entire recycling process, FormaTurf offers complete transparency thanks to a new three-stage tracking system.

Facility operators for the first time will be able to see exactly what happens to their old synthetic surfaces once they have been removed. QR codes attached to each individually installed surface will allow clients to clearly document the procedure, from immediately after removal thru to delivery at the Essen plant and on to the recycling process.

Because lengthy transportation routes account for a significant proportion of total recycling costs while also leaving a large carbon footprint, FormaTurf will focus on regional re-use. Located in the densely populated Rhine-Ruhr region, the area with the most turf pitches in Germany, Essen was strategically chosen to limit the environmental impact of the new company’s activities.

The plant will also be powered by 100% green energy. Every element connected to the future plant was also meticulously thought through in terms of energy and resource conservation – right down to the lighting, which will feature LED systems.

Not waste material, but raw material

Tom Beck, Managing Director of FormaTurf, says the new company adds an important dimension to the Polytan Sport Group: “At the end of its lifecycle, we do not consider a synthetic turf system to be waste material, but a raw material instead. We recycle the turf completely and turn it into new products. This is how we avoid waste while creating new values. What’s more, we are closing the recycling loop for synthetic turf within the Sport Group companies by setting up the recycling plant in Essen: from development and production by Polytan, to installation, maintenance, removal and subsequent recycling of the system, everything is handled within our parent company – Sport Group.”

Conclusion and outlook

By closing the value chain from R&D through to recycling – which no other company in Germany can offer – Polytan and FormaTurf are following through on our shared, medium-term goal to spearhead sustainable recycling concepts in Europe.

Thanks to our Green Technology efforts, we continue to confront the greatest environmental challenges of our time through:

The future clearly bodes well for Polytan’s synthetic turf systems, which are rapidly taking on a new sustainable, ecological and recyclable identity.

As Mathias Schwägerl, Managing Director of Polytan GmbH, puts it: “We see ourselves as pioneers of sustainability in our industry, and want to retain this status for many years to come.”